在往期的集微访谈栏目中,爱集微有幸采访了Semi Analysis首席分析师Dylan Patel,关于半导体产业链,包括主要晶圆厂的原材料及化学品选择、制程工艺、晶圆制造成本、封装生态以及对应工具和设备的成本研究等方面提出了一系列问题,并收到了十分有启发的答复。

问:半导体整体是否正在经历“供不应求”和“供过于求”的循环期?

答:在供需方面,该行业始终保持着非常谨慎的平衡。我们总是有这样一个周期,公司建造了大量产能,然后他们建造太多了,当需求放缓,就会产能过剩。在这种情况下,目前正在制造大量产能,但与此同时,由于能源、战争和房地产问题,全球需求正在放缓,然后全球各地的需求都在减少。

因此,等到所有这些晶圆厂都将完工并开始投产,潜在的需求将不再存在。那么这对行业的长期健康发展有什么影响呢?同时,我们也有了更多的补贴和更多的区域化,所有主要国家都想拥有自己的供应链。他们不希望自己的供应链是全球化的,希望在本国境内有获得供应链安全保障。他们通过行业补贴来实现这一目标。例如,欧洲已经通过了约400亿欧元的补贴,日本通过了约300亿日元的补贴,美国最近刚刚通过了520亿美元的芯片法案。它也花费数十亿的研究费用。中国的五年计划分析显示补贴、贷款和税收优惠可能高达2,500亿美元。

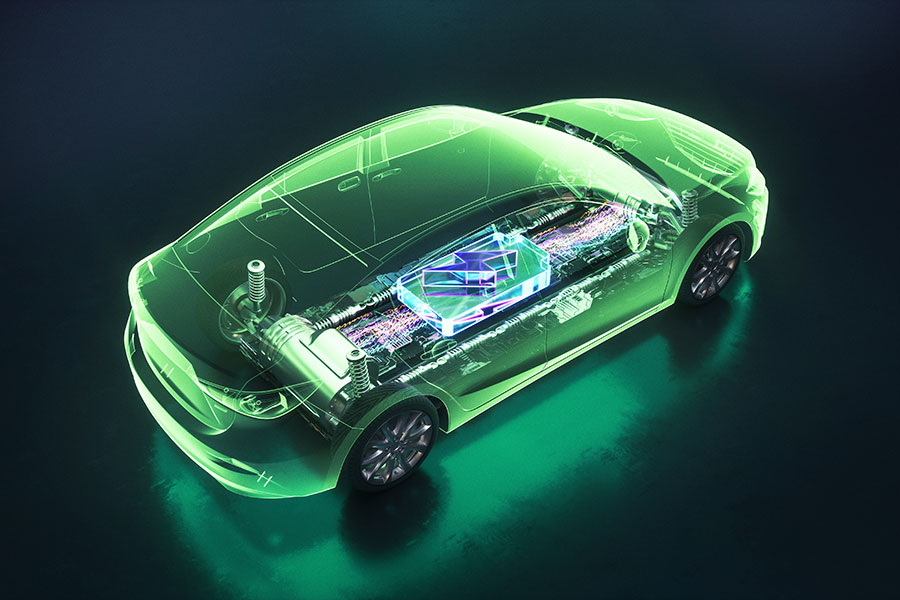

所有这些钱都将用于建造更多的晶圆厂。问题是需求是否会保持低水平,还是会再次调整,因为我们在这个行业存在很多趋势。数据中心、人工智能、5G、汽车和物联网,所有这些趋势都在快速增长。但最近,在过去6个月里,我们的业务大幅放缓。因此,从新年开始,我们会出现供应过剩吗?需求恢复需要多长时间?看来这可能是一个长期的需求放缓。如果所有这些晶圆厂都投产,更多的晶圆厂投产后再批准补贴,该行业可能会在许多领域出现长期的供过于求循环,而不仅仅是汽车碳化硅和氮化镓等领域。

他们可能会说,未来很长一段时间内会供应不足,但许多其他领域,如逻辑和28纳米、45纳米、90纳米这些类型的制程节点,特别是内存,可能会在多年内供过于求。这会导致利润大幅下降。所以我预计整合将会发生,因为现在这些行业中有很多公司。很多公司将无法在经济困难和供过于求中生存下来。所以表现好的公司会获胜,三星、SK海力士、美光和长江存储等闪存公司会生存下来。

我预计铠侠或西部数据会在闪存领域整合实力较弱的公司。那些资金不足的公司在逻辑领域也会发生同样的情况。例如,台积电、联电、中芯国际这些代工厂会存活下来,但其他的代工厂可能没那么幸运。所以那些财务状况较差的公司可能无法生存下去,由于该行业供过于求,它们可能需要被合并或收购。因此,因为存在大量竞争和供应过剩,许多三线代工厂不得不整合到更强的二线和一线代工厂中。我想提的另一点是关于晶圆厂的规模,如果企业允许从一家公司采购所有的半导体,而国家允许从全球几个地区采购所有的半导体,这有利于形成非常大的规模。一个月10万片晶圆并非从未有过。这仍然是很常有的事。每月生产10万片晶圆的晶圆厂效率明显高于每月生产2.5万或1万片晶圆的晶圆厂。事实上,我们的研究表明,每月生产10万片晶圆的晶圆厂效率比每月生产2.5万片晶圆的晶圆厂高30%。如果我们进行区域化,这可能意味着公司将在美国、中国、日本、台湾和韩国建造一个每月生产2.5万片晶圆的晶圆厂,所有这些国家可能建造每月生产2.5万片晶圆的晶圆厂,而不是每月生产1000或2000片晶圆的晶圆厂。因此,这些小型晶圆厂的效率会更低,这意味着每个晶圆厂需要更多的设备来支持这种水平的产出。这也需要大量的消耗品,如光刻胶和定位靶和硅晶圆,其中一些也需求也很容易增加。因为小型晶圆厂比大型晶圆厂浪费更多的化学物质,如CMP抛光液和光刻胶。

问:供过于求在整个半导体行业里是否更加严重,对供应商有何影响?您能预测一下供过于求会比以往更加严重还是更轻微?

答:我们分析总结出,供过于求将比2018年更严重。因为在2018年,供过于求主要出现在存储需求受限上。而现在,我们认为供过于求会更加严重,但此外,许多成熟制程的供过于求也会更加严重。在2018年,供过于求是因为我们的需求放缓,但我们的供应没有放缓。而这一次,由于战争、能源、房地产和新冠疫情,需求似乎进一步放缓。而且此时还有更多的晶圆厂投产。2018年,很少有公司建造90纳米、45纳米、28纳米晶圆厂,他们使用现有的晶圆厂。大部分的新晶圆厂都是存储或使用最新工艺的晶圆厂,几乎没有成熟工艺晶圆厂。但这一次似乎有更多的成熟工艺晶圆厂投产,所以尽管出现了5G、汽车和数据中心这些需求,可能仍会导致行业有供过于求的隐患。

问:您认为,对于设备和材料供应商,在面临供需严重失衡的市场挑战时,如何将财风险降到最低?

答:这些设备供应商和化学品供应商能够平衡供需的唯一方法是,在新一轮供应严重过剩的情况下,将业务多样化,进入需求比较多的领域。也许半导体设备会出现供过于求的情况。过了几年,也许一两年,供应就会放缓。然后,他们需要另一个可以依赖的业务。尽管半导体市场疲软,这一业务仍将增长。

问:一些无晶圆厂(如联发科)削减订单,违反与代工厂的LTA合同,如何解读这种现象?

答: 就长期协议而言,联发科是该业务中受创最严重的一个公司。由于向5G过渡,他们看到惊人的增长。但由于他们最大的智能手机市场出现疲软,他们不得不开始削减订单。因为他们不再接受订单,他们不想在资产负债表上留下旧芯片。他们削减订单,然后有芯片时接受订单。但问题是现在他们已经和一些代工厂签订了长期协议。总的来说,我认为联发科不需要向他们的代工厂付太多的罚款。而一些公司,就像我之前提到的,Qorvo不得不支付罚款。在很多情况下,长期协议并没有失效。他们在重新谈判。在高通的案例中,他们也有类似的问题。他们与格芯签订了长期的前端芯片协议。他们没有撕毁协议,而是决定重新谈判。高通延长了长期协议,协议又续了两年。他们减少了高通今年必须购买的芯片数量。最后,他们仍有一个长期的协议,但高通不必在今年储存大量的芯片,而联发科也可能会出现同样的情况。我对联发科的订单并不是特别的了解,但我知道高通发生了什么。所以联发科也很可能出现类似情况。

问:虽然我们已经听到半导体供过于求的消息,但一些统计数据显示,某些汽车芯片仍然处于短缺状态,您能解释一下原因吗?

答: 当然。所以行业中供过于求的领域不仅与工艺节点相关,还与产品类别相关。在这方面,电源管理IC和显示驱动器IC已经回到了供过于求,一些公司已经削减了代工订单。但还有其他类型的技术,比如模拟技术。它使用了一种类似的旧工艺技术,但它采用了一种非常专有的形式,所以这些模拟芯片仍然供应不足,像这些模拟芯片和一些传感类型的芯片仍然供应不足。由于汽车市场的增长和对汽车的预期,碳化硅和氮化镓等高功率半导体也供应不足。即使产能增加,这些会继续供应不足,因为产能增加不能满足目前全球转向电气化和绿色能源的需求。

问:在美国和欧洲的一系列芯片法案和政府激励措施的推动下,台积电、三星、英特尔和格芯正在扩大产能。因此,您能否分析一下 IDM和纯代工厂在计划扩大供应时的细微差别?

答:IDM和代工厂都在扩张,但代工厂的扩张方式不同。台积电在扩张方面更具策略性。他们将在美国生产5纳米工艺,在日本生产28纳米和16纳米级别的工艺,在中国生产28纳米工艺,但他们没有将新的高附加值的工艺转移到其他地方。例如他们不会在这些地区制造3纳米或2纳米工艺。他们目前在中国台湾建造的那些晶圆厂大多是那些工艺技术,而他们在中国台湾外建造的晶圆厂是更旧的技术,所以像台积电这样的代工厂有不同的战略。

这同样适用于格芯。他们在欧洲制造某些技术,但他们把FinFET节点和硅光子学技术保留在美国,他们在欧洲只制造FD-SOI,在欧洲生产45纳米和28纳米。

然后,如果我们看看IDM,他们很不一样。例如,三星正在韩国建设晶圆厂,但他们也很可能会在美国建造一个非常大的晶圆厂,而美国的这家大型晶圆厂预计将成为他们的领先技术,包括他们的全环绕栅极晶体管。

对于英特尔,他们把所有的前沿技术留在了美国,还有一些在以色列和爱尔兰。但有了新补贴,三星很可能会考虑在美国和韩国建设全环绕栅极技术的晶圆厂。英特尔将在俄亥俄州、欧洲比如德国建造全环绕栅极新晶圆厂。IDM愿意把他们的先进技术运到国外。随着韩国的三星把业务转移到美国。美国的英特尔也在把业务转移到欧洲。而台积电则把所有先进的3纳米、2纳米及更先进的技术都留在中国台湾。格芯将他们的硅光子学和FinFET留在美国,所以代工厂和IDM在如何建厂方面存在非常大的差异。

代工厂,尤其是台积电和格芯,在扩大供应的同时,要求大量预付款,并锁定供应协议,特别是在先进和落后节点上。但对于英特尔和其他IDM来说,这就有点困难了。他们不能与其他合作伙伴共同投资,因为他们是为整个工厂买单。所以我们看到一些客户不得不向格芯或台积电付款,以削减产能或推迟产能。而英特尔,如果他们供过于求,他们必须自己解决。他们不能问戴尔或联想,你们能为我们新建的产能买单吗,但我们实际上还没有开工。他们的客户不是这样的。所以在需求动态和所涉及的风险方面存在很大差异,至少一线代工厂获得了提前支付和长期合同,而一些IDM则承担了更高的风险。同样,二、三线代工厂也在承担很高的风险,因为他们没有锁定这些供应协议。

问:我们发现有些手机厂商在今年都遇到了库存问题,而手机厂商清库存的行为是否会加剧芯片过剩?例如苹果在 iPhone14 上用去年的芯片

答:在苹果这个例子里,我认为这更多的是成本问题,而不是行业供应问题,因为芯片尺寸并没有变得太大。这是类似的工艺技术。但使用LPDDR5的RAM要比使用LPDDR4X 的贵得多。所以我认为苹果这样做是出于成本原因,而不是供应过剩的原因。但总的来说,这确实导致了业务增长放缓。人们必须应对低端市场的需求,尤其是低端和中端市场的需求,然后再是高端需求,这是因为他们库存过剩。所以库存过剩意味着你会停止采购一段时间,过剩的库存将流向IC供应商。所以一些IC供应商不得不为恢复产能支付罚款。不仅仅是他们减少了产能订单,或者他们从需要更多产能变成不需要更多产能。事实上,一些公司已经因为减少产能而不得不支付罚款。例如,Qorvo的射频前端部门,因为智能手机供应商停止订购,所以他们前端5G芯片就过剩了。然后这就冲击到没有全部利用率的代工厂。几乎两年来,每个代工厂的利用率都接近100%或达到100%。最近看到中芯国际现在的利用率是96%,其他很多公司的利用率都在下降。他们的利用率不再是100%。所以问题是利用率多低时他们会没有盈利?因为利用率不再是100%。市场上会发生什么变化?

问:4G芯片为何会短缺?

答:当然。所以当供应受限时,供应商就会转移。他们转向更昂贵的高利润产品。如果你有产能,你会把所有这些都分配给利润率最高的产品——也就是5G芯片。随着5G手机需求放缓,现在对5G芯片的需求没有那么大了,但4G芯片依旧供应严重不足。这是因为人们为了追求利润导致4G 智能手机行业芯片供应严重不足。但现在,我不认为4G芯片供应不足,这一问题已经得到了解决。最近,一些5G芯片重新分配到4G供应。市场对低端智能手机的需求是最强的。所以这就是需求放缓和供应的问题,市场疲软很普遍。

问:我们知道现在有些手机厂商试图在手机里采用自研芯片,而目前产能过剩是否对这些厂商来说是个好消息?比方说更容易找到代工或者代工更便宜了?

答:我认为代工厂与其最大的客户有着独特的关系,全球四大半导体公司中有两家是联发科和高通。联发科和高通与台积电和三星的关系非常密切。台积电和三星的利用率因为经济放缓而降低,台积电还没有看到这一点,但他们可能会开始打折售出晶圆,但这些折扣将惠及所有人。他们不会优先考虑谷歌、vivo或OPPO,也不会优先考虑联发科和高通。事实上,最大的客户通常是那些获得最大折扣的客户。台积电在短缺期间停止了大批量折扣,大客户原本可以少支付10%或20%的价格。他们在短缺期间停止了这种做法。现在,随着短缺的结束,可能会恢复这些折扣。但只有给大客户折扣,这些大客户才会决定制造更大量的芯片,而不是冒险把产能给新客户或尚未证明其价值的小客户。因此,vivo、OPPO、三星和谷歌有可能更容易通过代工厂制造自己的系统级芯片。但他们也很可能不会得到这么好的交易。因为联发科和高通通常有较大批量的折扣。

以下是采访原文(英文):

Q: Is the semiconductor as a whole experiencing a cycle of ”shortage” and “oversupply”?

A:So with regards to the supply and demand, there's always a very careful balance of the industry. And we've always had cycles where companies build lots of capacity, and then they overbuild and demand slows, so there's too much capacity. In this case, there is a large amount of capacity being built currently, but at the same time, demand is slowing down across the world due to energy and war and real estate issues, then across the world demand is reducing.

And so all these fabs are going to be completed and start coming online, and potentially the demand will not be there anymore. And so what does that do for the long term health of the industry? And then at the same time, we also have more subsidies and more regionalization, right? All the major countries want to have their own supply chain. They want to not be global on their supply chain, have security within their own borders. And the way they're achieving this is by subsidizing industries, right? For example, Europe has passed about 40 billion euros worth of subsidies and Japan about 30 billion and the US just recently passed their $52 billion CHIPS Act. And then it has some billions of research as well. There's China whose five year plan has shown some analysis that it could be as much as $250 billion across subsidies and loans and tax benefits.

And so all of this money is going to be funneled into building more and more fabs. The question is whether demand is gonna stay low or revamp again, because we have many trends in the industry, right? Data centers, AI, 5G, automotive and IoT, all of these trends are growing so fast. But recently over the last 6 months, we've had a big slowdown in business. And so since the new year, will we have an oversupply ? How long will it take demand to return? It seems like this may be a longer term slowdown in demand. If that's the case with all these fabs coming online and then subsidies being passed until even more fabs coming online, the industry could have a long term cycle of oversupply in many areas, not all areas like automotive silicon carbide and gallium nitride.

Those will likely still say, under supplied for a long time to come, but many other areas such as logic and 28 nanometer, 45 nanometer, 90 nanometer, these sorts in the process nodes, and memory especially might be oversupplied for many years. And this would cause profits to fall significantly. And so I expect consolidation to occur as there's many companies today in some of these industries. And some many will not be able to survive financial hardship and oversupply. And so the best players will win, companies in the memory space like Samsung, SK hynix, Micron and YMTC, these companies will survive.

Maybe I expect kyoxy or Western Digital to consolidate in the weaker companies in the memory space. And those without as much funding, the same will happen in logic, right. For example, TSMC, UMC and SMIC. And these foundries will survive, but then other foundries like wang hong might not survive. And so those who are weaker financially may not be able to survive and they might need to be merged or bought up because of the weakness of an oversupply in the industry. So many tier three foundries might have to consolidate into the stronger tier two and tier one as there's a lot of competition and oversupply.

The other point I wanted to bring up is and with regards to the size of fabs, right? When companies were okay with sourcing all their semiconductors from one firm, and countries were okay with sourcing all their semiconductors from a few regions of the world. That was conducive to fabs being built into a very large size. 100,000 wafers a month is not unheard of, right? It's still a very normal thing. 100,000 wafers per month fab is significantly more efficient than 25,000 wafers per month fabs or 10,000 wafers per month fabs. In fact, our studies show that they're actually 30 % more efficient, 100,000 wafers per month fab than a 25,000 wafers per month fab.

And if we're doing the regionalization, that likely means that companies will build a 25,000 wafers per month fab in the US, in China, in Japan, in Taiwan, in South Korea, all of these countries might build 25,000 wafers per month fab instead of just 1,000 or 2000 wafers per month fabs. And so the efficiency will be lower with these smaller fabs, which means there will need to be more equipment in each fab to support that level of output. So that is also much consumables, such as photoresist and spotter targets and raw wafers, some of them will increase convenience as well. As there's more waste of chemicals, such as CMP slurry and photoresist in small fabs than there is in very large fabs.

Q:So can you predict whether the oversupply will be more severe or milder than before?

A:We summon analysis believe the oversupply will be more severe than in 2018. Because in 2018, it was mostly limited to memory. In this case, we believe memory will be more oversupplied, but furthermore, many of the trailing technologies will be oversupplied more as well. Because in 2018, we had the demand slowdown, but we didn't have supply slowdown. This time it looks like demand is slowing down more due to war and energy and real estate and Covid. But, furthermore, there's more fabs coming online. Very few people were building 90 nanometer, 45 nanometer, 28 nanometer fabs in 2018, they were just using existing fabs. Most of the new fabs were for memory or for leading edge. There were few trailing edge. But with this generation, this time it seems like there's a lot more trailing edge fabs that could cause a potential oversupply in the industry, despite trends of 5G and automobiles and data center.

Q:As for the equipment and material suppliers, how can they minimize the financial risk when they encounter challenges like seriously unbalanced demand and supply?

A:The only way that these equipment suppliers and chemical suppliers can balance the supply and demand, a new cycle of very severe oversupply is by diversifying into areas that aren't quite as weak great. Perhaps equipment for semiconductors falls into oversupply. And for a couple years, maybe a year or two, it slows down. Then they need to be able to have another business to rely on. That will grow despite the weakness in the semiconductor market.

Q:Some fabless companies(such as Mediatek) has cut back orders, violating its LTA contract with the foundries, how do you interpret this phenomenon?

A:So MediaTek is one of the hardest hit companies in the business with regards to their long term agreements. The growth they were seeing was amazing due to the 5G transition. But due to this big weakness in their largest market smartphone, they had to start cutting orders Because they stopped receiving orders, they didn't want to just keep old chips on their balance sheet. They cut orders and then they'll build orders as the chips come inBut the issue with that is now they've signed all these long term agreements with some foundries. In general, I don't think Media Tek had to pay much penalty to their foundries. Whereas some companies, as I mentioned earlier, Qorvo has had to pay a penalty. Or in many cases, long term agreements aren't broken. They're renegotiated. So in the case of Qualcomm, they had a similar issue. They had long term agreements with global foundries for front end chips. Instead of breaking the agreement, what they decided to do was they renegotiated. And Qualcomm made their long term agreement, more long term, they added another 2 years to it. They reduced the amount of chips that Qualcomm has to purchase in the current year. In the end, they still have a long term agreement, but Qualcomm doesn't have to be stuffed with a lot of chips that in the current year, and it's likely the same occurred with Media Tek. I have no special source on Media Tek orders, but with Qualcomm, I know that's what happened. So with Media Tek, it's also likely similar.

Q:Although we have heard news of oversupply of semiconductor, some statistics shows that certain automotive chips are still in shortage, could you explain why?

A:So the areas of the industry that are in oversupply don't just tie to process nodes, but also sub categories. In that regard, power management ICs and display driver ICs are back into oversupply territory already with companies that are already cutting their foundry orders.But then there's other types of technologies such as analog. This uses a similar, older, process technology, but it uses a very specialized form, and so that those analog chips are still very much undersupply, things like these analog chips and some sensing types of chips that they're still in undersupply. High power semiconductors, such as silicon carbide and Gan, those are also undersupplied because of the growth in the automotive market and expectation of vehicles. Those are gonna continue to be under supplied even as capacity ramps, because the capacity ramp does not meet the current demand that the world is headed for in terms of electrification and green energy.

Q:Driven by series of Chip Act and government incentives in U.S and Europe, TSMC, Samsung, Intel and Globalfoundries are expanding their capacities. could you analyze the subtle difference between IDM and pure foundries when they are planning to expand their supply?

A:The IDMs are expanding as well as the foundries, but the foundries are expanding in a different way? TSMC is being much more tactical about where they expand. They are gonna build 5 nanometer in the US and they're gonna build a 28 nanometer and 16 nanometer. And in that class of technology in Japan and 28 nanometer in China, but they're not moving any of the new high volume production, right? They're not moving three nanometer or two nanometer. Those fabs that they're building currently in Taiwan are mostly those process technologies, whereas they're building the more older technologies outside, so foundries like TSMC have a different strategy, right?

The same applies to GlobalFoundries, right? They're building certain technologies in Europe, but they're keeping the FinFET nodes and silicon photonics in the US, they're only doing FD-SOI in Europe, and they're doing 45 nanometer, 28 nanometer in Europe.

And then if we look at the IDMs, they're very different, right? Samsung, for example, is building capacity in Korea, but they're also very most likely going to build a very large fab in the US and that large fab in the US is expected to be their leading edge technology, including their gate all around transistors.

And with Intel, they have kept all their leading edge within the US and some in Israel and some in Ireland. But with the new subsidy, Samsung is very likely considering to build gate all around technology in the US as well as in Korea. Intel is going to build new gate all around fabs in Ohio and in Europe, in Germany. The IDMs are willing to ship their advanced technology outside of their home borders, right? With Samsung in South Korea are moving to US as well. And Intel in the US are moving to Europe as well. Whereas TSMC is keeping all of their advanced, three nanometer and two nanometer and beyond in Taiwan. And GlobalFoundries is keeping their silicon photonics and FinFET in the US, so it's a very big difference in how some of these foundries are treating their buildouts versus the IDMs.

The foundries, especially TSMC and GlobalFoundries, are demanding many prepayments and locked in supply agreements as they're expanding their supply, especially on advanced and trailing nodes. But with Intel and other IDMs, it's a little bit more difficult, right? They can't have a co-investment with another partner, because they're the one footing the bill for the entire fab. And so we've already seen some customers have to pay GlobalFoundries or TSMC in order to cut back on capacity or push to delay their capacity to a later date. Whereas Intel, if they have an oversupply, they have to deal with that on their own, right?They can't tell Dell or Lenovo, can you pay for the capacity that we built, but we didn't actually run. That's not how their customers work. And so there is a big difference in the dynamics of the demand and the risk involved where the foundries, at least the tier one foundries are getting prepayments and long term contracts, while some of the IDMs are taking a higher risk. And likewise, the tier two and three foundries are also taking high risk because they don't have these locked in supply deals.

Q:We found that some mobile phone manufacturers have encountered inventory problems this year. Will the behavior of mobile phone manufacturers to clear inventory will aggravate the oversupply of chips?

A:In the case of Apple, I believe that's more of a costing than a industry supply thing because the chip size isn't too much larger. It's the same, it's a similar process technology. But the RAM going LPDDR 5 versus LPDDR 4 x is much more expensive.So I think Apple was doing it for a cost reason, not a oversupply reason. But overall that does contribute to a slower ramp in the business, right? People having to deal with lower end market demand, especially in the low end and in the mid-range and then stacked on top is that they have excess inventory. And so this excess inventory means you stop purchasing for a time that flows through to the IC vendors and suppliers. And so some IC suppliers have already had to pay penalties for giving back capacity, right? It's not just they reduce their capacity orders, or they went from needing more capacity to not needing more capacity. Some have actually had to pay penalties for reducing their capacity already. For example, Qorvo in the radio front end department because smartphone vendors have stopped ordering. And so they have extra front end 5G chips. And then that knocks into the foundries who are not at full utilization, right? Every foundry has been at near hundred percent utilization or a hundred percent utilization for almost 2 years now. Recently it started to see SMIC is now 96 % and many others are falling. They're not at 100 % anymore. So the question is how low will they stop turning such a profit? Because they're no longer at 100 %. What happens in that? What shakes out in the market?

Q: That's very interesting, because we, and it's let me remind that we heard that some 4G chip, 4G SoC trip are still in short supply. So can you, could you just explain why have this phenomenon?

A:So suppliers shifted up when there's supply constraints. They shift up into the more expensive high margin products. If you have the capacity, then you're going to allocate all of that to the highest margin product. And so that was the 5G chips. And as a slowdown happened, there's now not as much of a demand for those 5G chips. There was a big undersupply of 4G, right? That was the part of the market that had the biggest undersupplying the smartphone industry as 4G because everyone prioritized it due to profits.And now, though, I don't believe there's much of us undersupplying 4G chips anymore, that has been corrected. As of recently as the 5G chips got some of the reallocated to 4G their supply and some others. The weakening and the demand for the low end smartphone is the strongest, right? So that's the slowdown and supply and the weakness is most prevalent.

Q:We know that some smartphone manufacturers are trying to use their own silicon in their products. Is the current overcapacity good news for these manufacturers?

For example, it is easier to find a foundry or the foundry is cheaper。

A:I think the foundries have a unique relationship with their largest customers, and two of the four largest companies in the world for semiconductors are Media Tek and Foxconn. And Media Tek and Foxconn have very close relationships with TSMC and Samsung.So as TSMC and Samsung have lower utilization rates due to a slowdown, TSMC hasn't seen it yet, but they might start discounting wafers, but those discounts are gonna go to everyone, right? They're not going to prioritize Google or vivo or oppo any more than they would prioritize Media Tek and Qualcomm.And in fact, the biggest customers generally are the ones that get the biggest discounts. TSMC ended a lot of their volume discounts during the shortages where larger customers paid 10 or 20 % less. They ended that during the shortages. Now, with the shortages ending, it's possible that these discounts will come back. But only for the largest customers and those largest customers will then decide to build larger chips rather than risking that capacity on this new customer or a small customer that hasn't proved their volume.So it could be possible that it's easier for vivo and oppo and Samsung and Google to build their own SoCs with foundries. But it's also very likely that they will not receive as good of a deal. As Media Tek and Qualcomm have generally have larger volume discounts.